Engineering (Concept Development)

Starting the development process for a 3D printed watch begins with defining the core concept whether the goal is a functional timepiece, a design prototype, or a wearable fashion statement. From there, the process moves into researching existing watch designs, identifying opportunities for innovation, and selecting materials that balance durability, printability, and comfort for daily wear. Initial sketches and CAD models are created to establish proportions, ergonomics, and mechanical integration points for the watch movement, straps, and fasteners. Iterative prototyping with 3D printing enables rapid refinement of the design, allowing adjustments to tolerances, aesthetics, and functionality before committing to more detailed engineering or final production methods. This early stage sets the foundation for both the technical performance and the user experience of the watch.

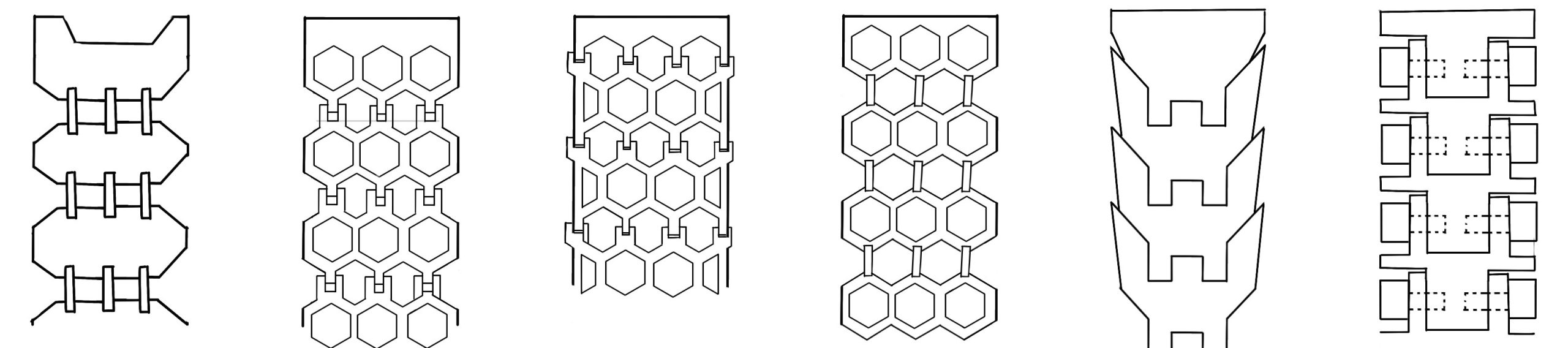

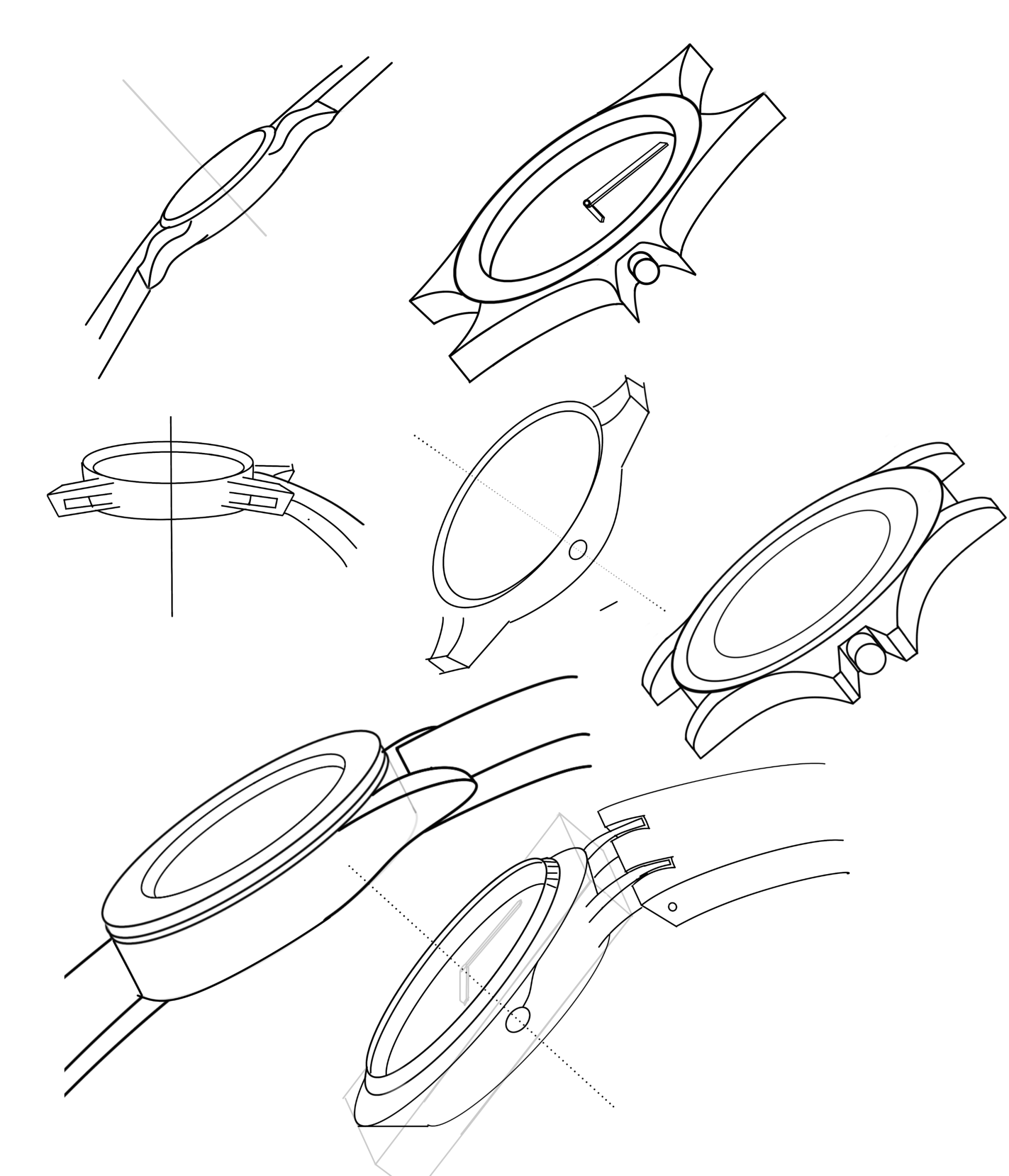

Sketching concept art for a 3D printed watch band is the first step in bringing abstract ideas into a tangible design direction. This stage is all about freely exploring forms, proportions, and functional elements without the constraints of software or manufacturing limitations. We started with quick, loose sketches to capture the overall silhouette of the band, experimenting with clasp mechanisms, strap widths, and surface patterns that could later translate into unique printable geometries. Iterations may focus on how the band flows around the wrist, how various geometries might enhance flexibility and breathability, or how aesthetic details can complement the watch face itself. These drawings not only act as a visual brainstorming tool but also serve as a communication medium, allowing others to quickly understand the design intent before moving into digital modeling or prototyping.

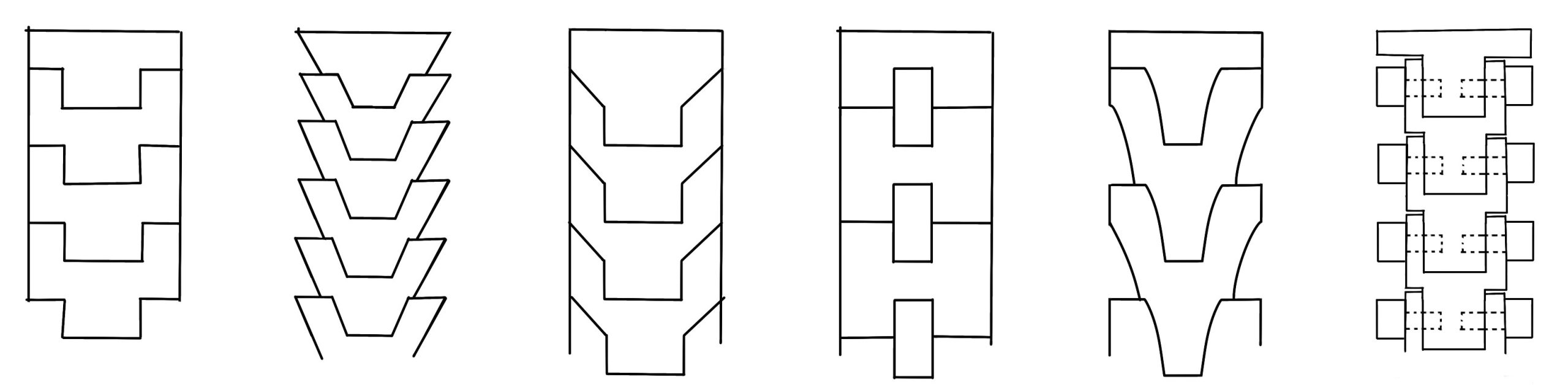

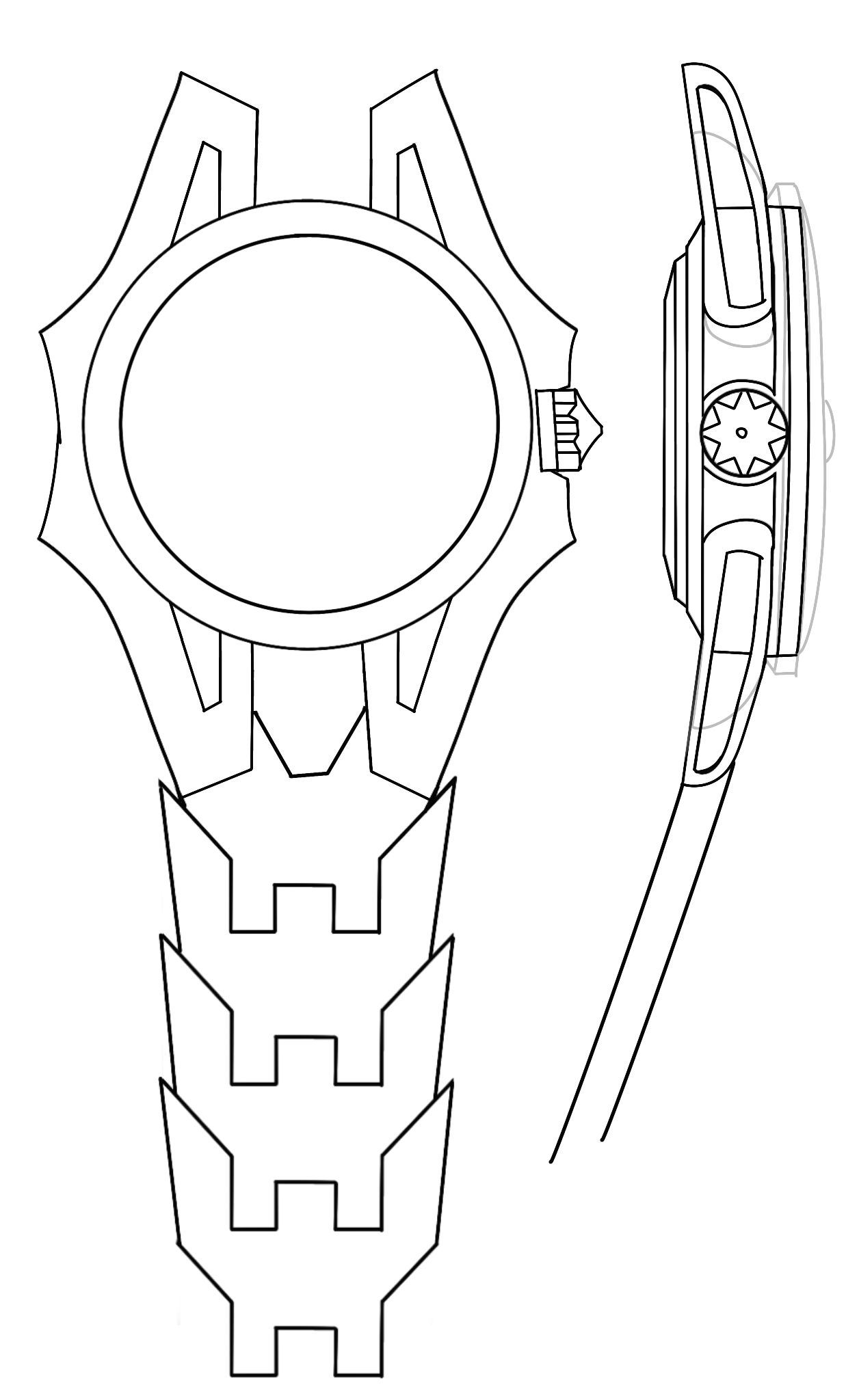

When sketching the body of a watch, we treat the brainstorming phase as the foundation of the design process. At this stage, we generate quick, iterative sketches to explore different case shapes, bezel profiles, and proportions, giving us the freedom to test how each idea balances aesthetics, comfort, and functionality. These early drawings allow us to think broadly and creatively, uncovering unique design directions from subtle curves that enhance ergonomics to bold contours that establish a strong visual identity. By externalizing ideas on paper, we create a visual roadmap that guides later stages of digital modeling and prototyping, ensuring that the final watch body is not only engineered with precision but also thoughtfully envisioned from the very beginning.

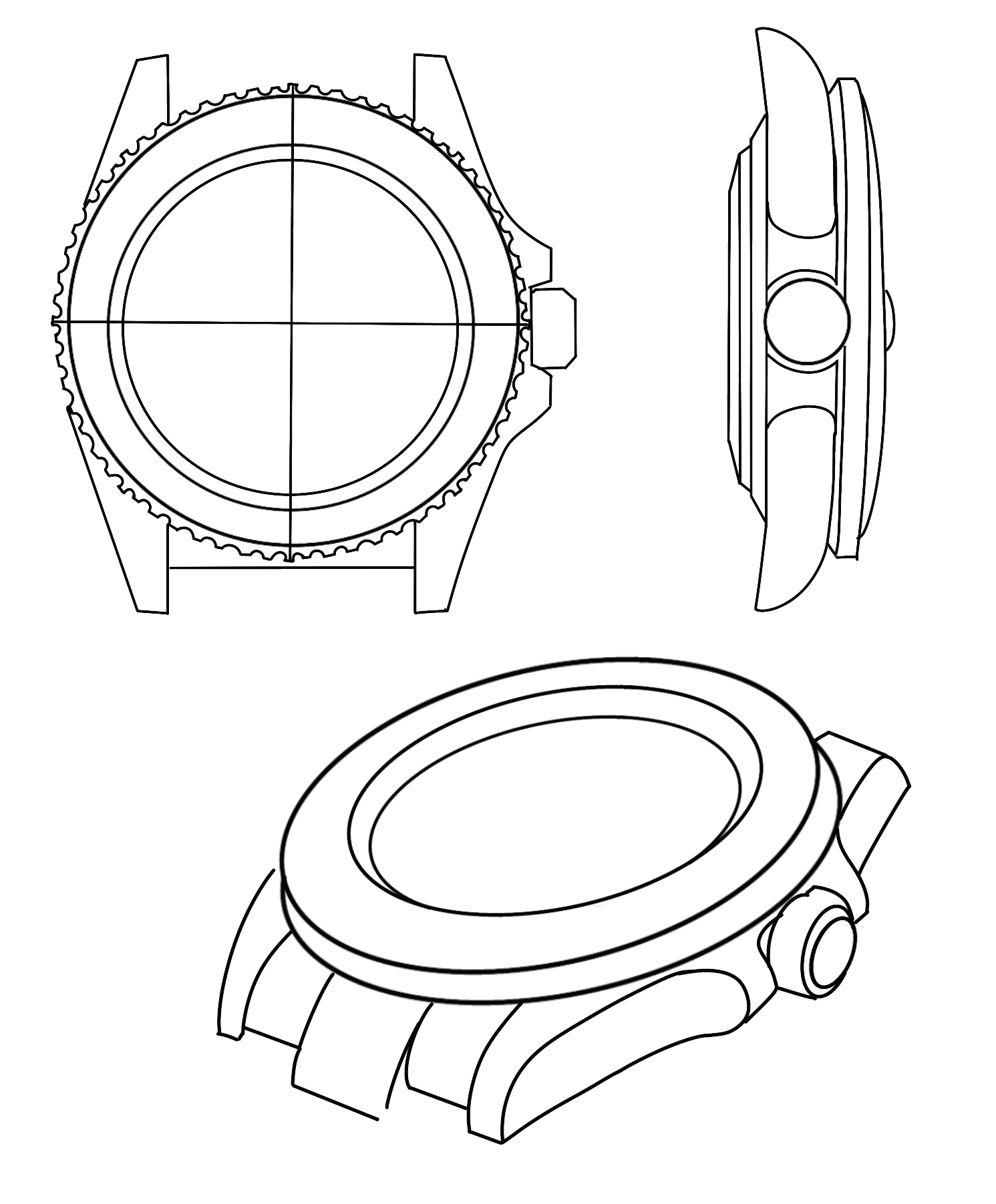

Through 3D modeling, we are able to rapidly draft and iterate on watch designs, turning initial concepts into precise digital models almost instantly. This process allows us to explore a wide range of case shapes, band geometries, and ergonomic features, testing both form and function before creating physical prototypes. By leveraging 3D printing, we can quickly produce tangible versions of these models, evaluate their fit and aesthetics, and refine details that would be difficult to perfect through traditional manufacturing. This combination of digital modeling and additive manufacturing accelerates concept development, fosters creativity, and enables us to bring innovative, customized 3D printed watches from idea to reality with efficiency and precision.